Cut-off wheels are essential tool accessories in many industries, from metalworking to construction. These tool accessories need to be strong, durable and safe to use. That is why safety standards and testing must be followed to ensure the quality of the cut-off wheels.

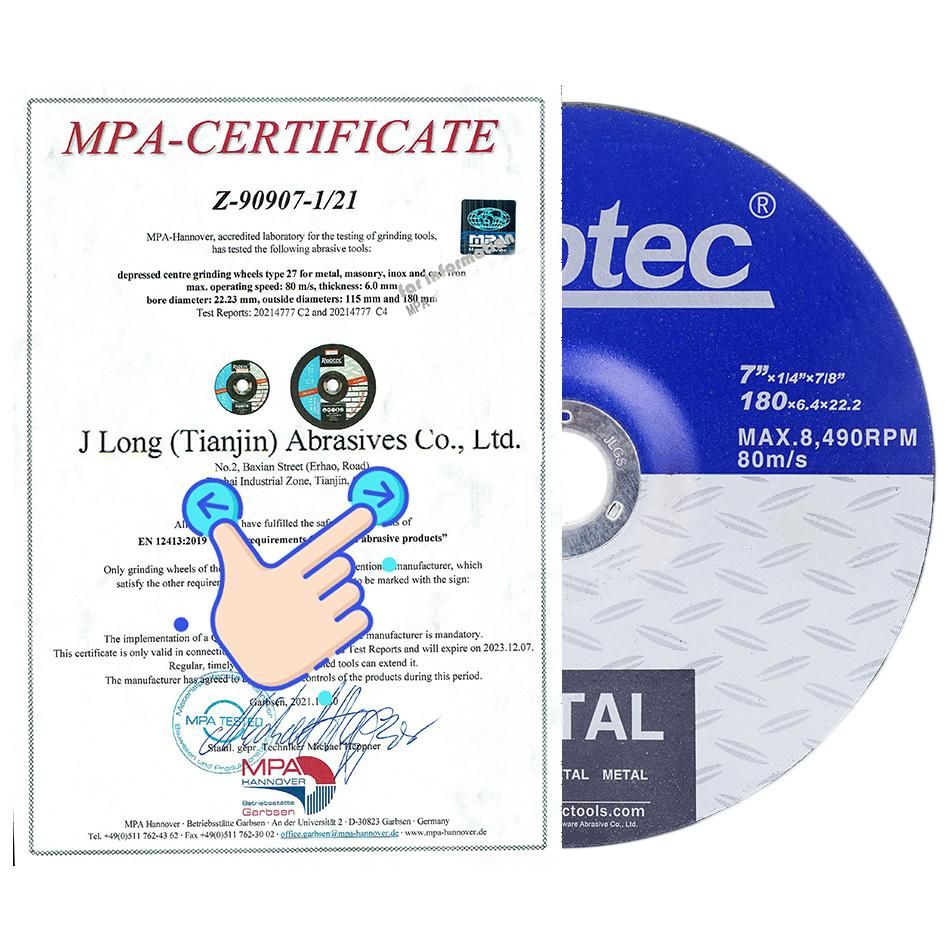

One of the most common international standards for testing cut-off discs is EN12413. This standard covers a range of safety requirements for cut-off wheels. As part of the compliance process, cutting discs must undergo a testing procedure known as the MPA test.

The MPA test is a quality assurance tool that ensures cut-off wheels comply with the EN12413 standard. MPA testing is performed by independent laboratories that are accredited to perform safety testing on cut-off discs. The test covers all aspects of disc quality, including tensile strength, chemical composition, dimensional stability, impact resistance and more.

For cut-off discs to pass the MPA test, they must meet all safety requirements and pass strict quality control checks. The MPA test is a reliable way to ensure that the cut-off wheel is safe to use and meets all safety requirements.

If you are a cut-off wheel user, you should look for products that pass the MPA test. This is your assurance that the discs you use are high quality, safe and comply with international security standards.

In addition to MPA testing, there are other quality assurance tools that can be used to ensure the safety of cut-off wheels. For example, a manufacturer may conduct in-house testing of cut-off wheels to ensure that their products comply with EN12413 requirements.

Some characteristics of cutting discs that require testing and monitoring to ensure their safety include:

1. Size and shape: The diameter and thickness of the cutting disc must be suitable for the intended equipment.

2. Speed: The cutting disc must not exceed the rated maximum speed of the equipment.

3. Bonding strength: The bond between the abrasive grains and the disc must be strong enough to prevent damage to the equipment and prevent the disc from flying away during use.

4. Tensile strength: the cutting disc must be able to withstand the force generated during use.

5. Chemical Composition: The material used to manufacture the cut-off wheel must be free of impurities that would weaken the cut-off wheel.

In conclusion, safety is the top priority in the manufacture and use of cut-off wheels. The MPA test is an important tool to ensure that cut-off discs comply with the EN12413 standard. Before purchasing cut-off wheels, make sure they have been tested by MPA to ensure their safety and quality.

Post time: 18-05-2023