According to the development of machinery industry, more and more machinery product need to be processed.Normally, the finished machinery product is processed by cutting, grinding and polishing.

There is a fact that the quality of abrasive wheels in the market is greatly different. The main complaining for the quality is “the short durability of abrasive wheels”, “The low sharpness for the abrasive wheels”, and “the accident happened during using”.

So select the abrasive wheels correctly is very important.

There are some tips to be shared as below

1. Choose the brand correctly.

There are several thousand manufacturers for the abrasive wheels in China, with different quality and price. A big factory (Such as J LONG) always could guarantee the quality not only because of their strict quality control system, but also they have good after-sales service.They have professional team to give you professional advice for using or selection of the product. And also they have the ability to make the product to fit your special requirement.

2. Select the correct abrasive wheels according to the material you will processed.

For example, when the material is very hard or have large area to be processed, the sharper disc is better choice; When the material is soft or the area is smaller, the durable disc is better choice.

3. Select the abrasive wheels according to the machine you using

When the power of cutting machine is big, Durable abrasive wheels with higher working speed is better choice. When the cutting machine has lower power, thinner and sharper disc is better.

The RPM of machine should not exceed the RPM marked in the disc.

4. Select the abrasive wheels according to the material being processed.

There are several abrasives for different material to be processed, such as Brown fused Aluminum, White fused Aluminum, Silicon carbide and so on.

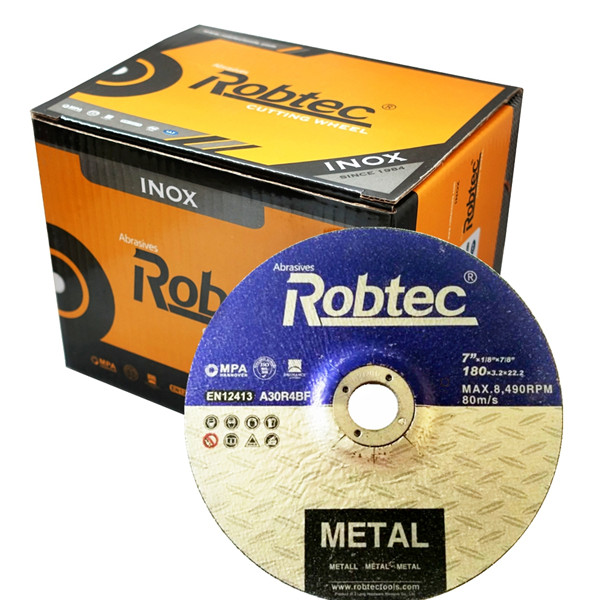

The brown fused Aluminum is mainly for all kinds of ferrous metal; the white fused Aluminum is mainly for stainless steel; And silicon carbide is mainly for granite, stone, ferrous metal and so on. Normally you could find the material, application, RPM in the label of abrasive wheels.

In one word, safety is the basic requirement for the abrasive wheels. Good quality abrasive wheels should have perfect balance on durability and sharpness, no burning to the material processed, and have good performance on all kinds of material.

Post time: 20-10-2022